Børresen M3

24 hour support

Payment options

Børresen M3 - Uncompromising high-end speaker with sublime sound quality

The Børresen M3 is an uncompromising floor speaker that reproduces your recordings with the absolute greatest realism and authenticity. In the past, loudspeakers have never been able to reproduce the recordings with the same realism as a live concert, but with the M3 series, Børresen has transcended this limit. Here you get a unique sound reproduction in a slim and elegant design, which makes them a testament to Børresen's constant pursuit of perfection.

The mission of the M series is to challenge the existing technological limitations and pioneer completely new and unorthodox areas of audio technology. It has resulted in a completely new design of speaker components, effective ways to combat resonance and vibration, and materials that provide the ultimate properties to raise sound quality to a level never seen before.

3D-printed basket in Zirconium

The M3 loudspeaker's basket is a true revolution – it is a topology-optimized 3D printed basket made of zirconium, which ensures maximum rigidity and thus minimum vibration and resonance. The basket is not just a placeholder for the membrane, because the energy generated by the membrane is also held by the structure behind it. The goal was therefore to eliminate the noise from the basket by designing a basket with maximum stiffness. Studies were conducted using computer-optimized finite element design, resulting in a topology-optimized 3D-printed basket made of the exclusive zirconium.

Børresen have not only designed a basket with an extreme stiffness - they have also added important factors such as huge internal damping and resonance control, resulting in extreme clarity in the overall performance. Thanks to the 3D printing process, the cavities are filled with zirconium powder, which gives the curve additional damping properties. Zirconium is by far the best choice of material as it allows the curve to generate an incredibly natural sound.

A bass/midrange diaphragm with maximum stiffness and minimal noise

The membrane is designed to achieve maximum stiffness with minimum noise. The membrane for the M3 is the most advanced and sophisticated speaker membrane on the market. The M3 membrane has the highest stiffness and the lowest membrane resonance. The technological demands for this unmatched, world-class diaphragm performance made it necessary to design, develop and assemble all components in-house. Michael Børresen and his team had to construct a large number of different variants and models until they achieved their uncompromising goal of ultimate diaphragm performance for unprecedented sound quality.

The result is a membrane that consists of four layers of laminates for a single unit: two layers of spread tow carbon fiber, a layer of aramid honeycomb in between and a titanium layer with Ansuz Supreme coating.

The combination of all these materials gives this state-of-the-art membrane its unique properties. Spread tow carbon fiber is designed to ensure a skin with optimal stiffness in many different directions. This unique characteristic reduces sound-disturbing vibrations and resonances to an unprecedented low level. This also applies to resonances in the frequency range above 8 kHz. As the diaphragm/speaker is used up to the 2.5kHz range, disturbing resonances have been moved two octaves outside the effective frequency range, ensuring an absolute minimum of resonances. Aramid honeycomb also has the best stiffness to weight ratio in the vertical direction.

Titanium has perfect resonance control properties and supports a natural, organic sound of the membrane. With the Ansuz Supreme coating, the skin's membrane is further acoustically optimized. This coating is applied to the titanium skin in a Hi-PIMS (High Power Impulse Magnetron Sputtering) machine to create the finest and most uniform layer of zirconium, followed by a layer of tungsten and finished with a layer of aluminum chromium nitride. This coating gives the music a truly impeccable sound quality.

An iron-free magnet system with silver

The patented Børresen iron-free magnetic system has been further refined. Børresen uses iron-free drivers in all its speakers. Their inductance is approximately ten times lower than that of conventional drivers. This extremely low inductance has now been further reduced to an unprecedented new minimum level – approximately 12 times lower than the inductance level of conventional iron-based drivers. This is because silver has 6-8% better conductivity than copper, and Børresen has replaced the copper polishing rings with in-house manufactured, handcrafted silver rings.

To take advantage of all the performance-enhancing sound properties of the Børresen M series, all other metal parts of these premium speakers also undergo cryogenic treatment. This reduces their inductance by another 6-8%. The result is perfect musical purity. With their unadulterated authenticity of music reproduction, these premium speakers set a new and unrivaled standard – clarity, refinement and sound design at its very best.

Cryogenically treated for a huge improvement

Cryogenic treatment of all metal parts of the speaker results in a further significant improvement in conductivity – thus releasing the finest and most subtle musical details. When metal parts undergo cryogenic treatment, they are subjected to extreme cooling. In the wake of this process, the metal structure contracts more and more. Alloying elements are pushed out of the grain structure of the metal, which now becomes very similar to a single crystal. These structural changes in metal have a profound effect on its sound properties, resulting in a 6-8% increase in conductivity.

All metal parts of these speaker series undergo cryogenic treatment. The cryogenic treatment cycle requires a time window of 3 days. Within the first 24 hours, the metal undergoes a cooling process from room temperature to cryogenic temperatures. During the next 24 hours, metal parts are held at temperatures around -196°C (-321°F) before the temperature, within the next 24 hours, gradually returns to room temperature. The gradual cooling and heating is essential to avoid thermal stress. The process strengthens and compacts the grain structure of metal parts and reduces the inherent residual stress that occurs when metal solidifies from its liquid phase to a solid phase.

Børresen treble with extraordinary efficiency

Elaborate finite element methods have been used to linearize and optimize the magnetic flux field, to facilitate driver movement and ensure high efficiency and exceptional linearity.

The efficiency of this closed-band tweeter amounts to an extraordinary 94dB and operates from approximately 2.5 kHz upwards. The moving mass is extremely low at 0.01 grams. The completely hidden treble has the capacity to work at an incredible speed, which is an absolute prerequisite for unlocking the most subtle and refined sonic details of any kind of music. The tremendous robustness of this tweeter allows it to handle extremely high transient peaks without any ear-fatiguing dropouts. No transformers are used.

Series connection for a coherent system

Børresen loudspeakers are equipped with a series connection configuration. The reason for this is that drivers share the same flow of electrical current in the crossing area. As a result, the electric current is phase-locked across the junction region. Unlike standard parallel filtering, where each driver receives its own frequency and phase content, the new series filters work by redirecting out-of-band currents around the current currents, creating a much more coherent system. This unparalleled and innovative technological approach takes your music to a new echo of acoustic joy.

For the crossover filter, Børresen has also gone to great lengths to find the best and most sophisticated state-of-the-art components. The coils are foil types wrapped with paper insulation and impregnated with resin under vacuum to make them mechanically extremely solid and stable.

For junction capacitors several rows of small military spec stack foil types have been used. They have the best mechanical stability and lowest inductance of any type of capacitor on the market (and they sound wonderful too). For damping resistors for the treble, use metal strip types, as they have by far the lowest noise figures and, furthermore, a very low thermal variation.

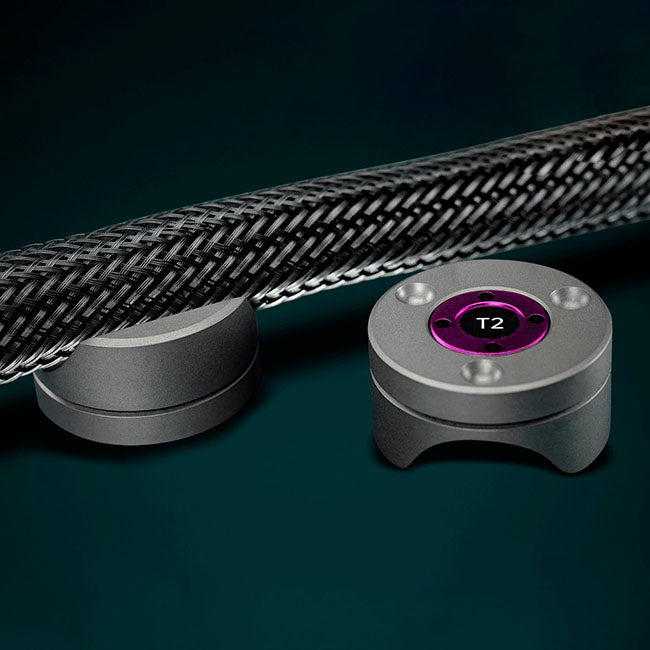

A redesigned and reinforced cabinet

The design is an evolution and optimization of Børresen's fantastic 0-series cabinet. To ensure even higher performance, the M3 enclosure is constructed with an additional 5mm of reinforced, block-milled, pressed wood structures. In addition, braces are built into the sides of the speaker to give the cabinet even more rigidity and mechanical stability. The treble and bass sections are equipped with matched terminals to ensure maximum efficiency. The cabinet is covered with black piano lacquer.

Internal cabinet M – Improves balance

The larger cabinet has also improved ventilation behind the bass/midrange nozzles. This results in less compression and thus a much faster and more flexible speaker driver, which has a significant positive impact on the overall sound image. In addition, the bass is equipped with a bass reflex section inside the cabinet, which ensures a dynamic and harmonious balance between midrange and bass.

The M3 driver configuration

The M3 is equipped with 4 unique 4.5″ M-series units. These drivers are connected in series in pairs so that one pair acts as a bass/midrange and another pair acts as a bass speaker driver. This approach ultimately results in increased speed, precision and depth, enriching the speaker with much more musicality.

Bi-amping

Both the M3 and M6 offer the option of bi-amping, allowing you to feed the bass and midrange/treble sections individually. This not only provides sufficient power to each section, but also results in a cleaner, more accurate sound.

These speakers are designed with two types of bi-amping in mind. The first is speaker crossover bi-amping. The frequency between the bass section and the midrange/treble section is optimized according to the M3 and M6 design to provide the best performance.

The other option is active crossover bi-amping, where you can adjust the crossover frequency yourself. This type of crossover is the optimal solution for fine-tuning your speakers according to the acoustic characteristics of your listening room, allowing you to control the amount of bass and the balance between bass and midrange/treble. To further enhance your listening experience, Børresen's sister company, Aavik Acoustics, has developed a high-end Analog Active Filter that works seamlessly with these new speaker models and provides the ultimate in precision and clarity.

Internally wired with Ansuz Gold Signature

The M3 is equipped with Ansuz Gold Signature cables, representing the very best in audio cable technology. These cables ensure an extremely clear, natural and authentic sound reproduction that lets you hear every nuance of your music.

The Tesla Coil Principle

The Børresen M3 uses Tesla Coil technology that eliminates noise and improves musical clarity. This advanced technology works by generating opposite voltages to neutralize noise, resulting in significantly improved sound reproduction.

Active Square Tesla Coils

With active square Tesla coils integrated into the circuit boards, the M3 achieves an impressive noise reduction, which ensures a cleaner and more accurate sound reproduction.

Analog Dither Technology 3rd Generation

The third generation of Ansuz analog dither technology ensures an even greater improvement in sound quality by amplifying the musical signal and reducing background noise, providing an even more detailed and open sound experience.

Anti Aerial Resonance Coil Technology

The M3 is equipped with Anti Aerial Resonance Coil Technology, which effectively eliminates airborne noise and ensures a clean signal transmission without interference.

Test of Børresen M3

Videos

Choose options